Precision laser welding machine is a kind of high-precision and high-efficiency welding equipment, mainly used for the welding and processing of precision parts. The core component is a laser generator, which emits a laser beam with high energy density to melt and fuse the welding material, so as to achieve the purpose of welding. Let's take a look at the working principle of precision laser welding machine in detail.

First, laser device

The laser device of the precision laser welding machine is the heart of the entire equipment and is also its core component. The laser device is mainly composed of laser source, beam transmission system, scanning mirror and optical protection system. The laser uses a fiber laser or a semiconductor laser, and its output wavelength is generally 1064nm. The laser beam is transmitted through the optical fiber or lens to the scanning mirror, which is screened and filtered by the photoprotection system, and finally forms a beam of high energy density for melting and fusing the welding material.

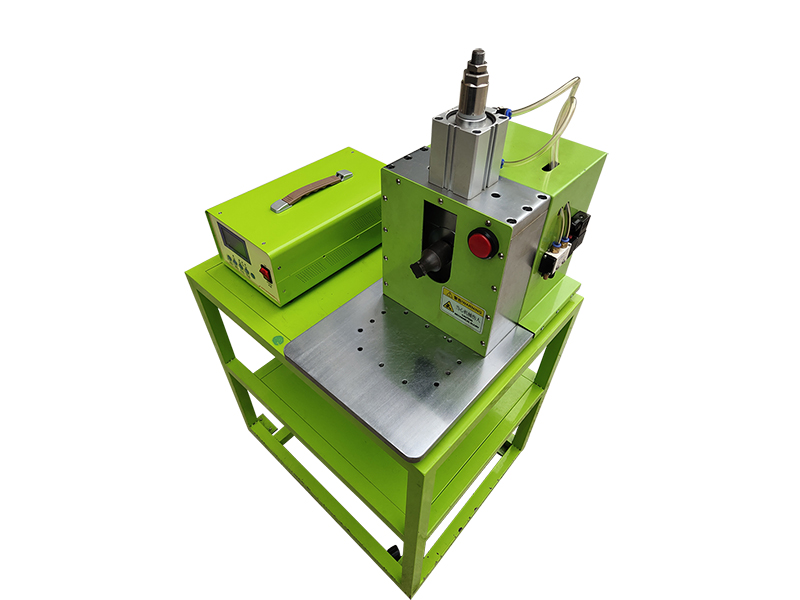

Second, welding table

The welding table is another important part of the welding device. Its main function is to provide a stable welding platform and fixture support for welding materials to ensure the stability and accuracy of welding materials during the welding process. The welding table is generally controlled by numerical control system, which can achieve high precision and high efficiency welding. Welding table is usually made of aluminum alloy, stainless steel and other high-strength materials, with corrosion resistance, wear resistance, high temperature resistance and other characteristics.

3. Welding process

In the welding process of the precision laser welding machine, the welding material needs to go through the following steps:

1, positioning alignment: by adjusting the welding fixture, the workpiece to be welded positioning alignment.

2. Prepare the welding area: clean the area with the registration code with cleaning solution or other methods to make it smooth and unobstructed.

3, laser welding: the laser beam is focused on the welding area, so that the welding area instantly heats up to above the melting point, the material melts, and fuses with the adjacent part.

4, cooling curing: After the welding area is cooled, the solder joint is cured into a whole.

5, remove welding traces: the use of grinding and other methods to remove the traces of the welding area, so that the workpiece weld looks very smooth and smooth.

中文(简体)

中文(简体)

Wechat

Wechat